Technology that can scavenge mechanical energy from biological or environmental vibrations and movement is in hot demand for self-powered devices, ranging from sensors and consumer electronics to defence. While piezoelectric materials have demonstrated great promise for converting mechanical energy into electrical, challenges remain.

“There is a lack of options for scalable manufacturing and integrating piezoelectric nanomaterials at a high-production rate and with good reproducibility,” says Wenzhuo Wu, the Ravi and Eleanor Talwar Rising Star Assistant Professor of Industrial Engineering at Purdue University in the US. “Obstacles concerning scalable, economical production of related materials continue to prevail, which limits the application potential of related materials.”

In his latest work, Wu and colleagues at Purdue University, The University of Texas at Dallas and Idaho National Laboratory in the US use scalable nanomanufacturing and self-assembly techniques to produce tellurium nanowire piezoelectric devices. Exploiting the high piezoelectric response and deformability of their devices they demonstrate their application for monitoring the inflation of a balloon catheter as well as a wearable cardiovascular sensor.

Nano benefits scaled up

As Wu points out, researchers had studied similar aspects of bulk tellurium before in the 60s and 70s, but the results did little to encourage much further investigation for exploiting the material in piezoelectric applications. “I think the main reason for the lack of studying the piezoelectric property of tellurium is probably because of its narrow bandgap and high carrier concentration in the bulk form, which would screen the effect of piezoelectricity,” he adds.

Key to the success of the current devices is the use of nanowires. Building on work reported in 2013 by Zhong Lin Wang at Georgia Tech in the US, Jae Min Myoung at Yonsei University in Korea and coworkers, Wu and his collaborators were able to produce tellurium devices with a vastly improved performance by exploiting the size-dependence of the bandgap and piezoelectric response.

In addition they controlled the diameter of the nanowires through the choice of solvent in the synthesis and demonstrated improved performance for nanowires with thinner diameters. They then produced single layer thin films of nanowires with a diameter of 7nm and an aspect ratio of 1000:1 using a standard “Langmuir-Blodgett” chemical process. Both synthesis and self-assembly are scalable.

On the pulse

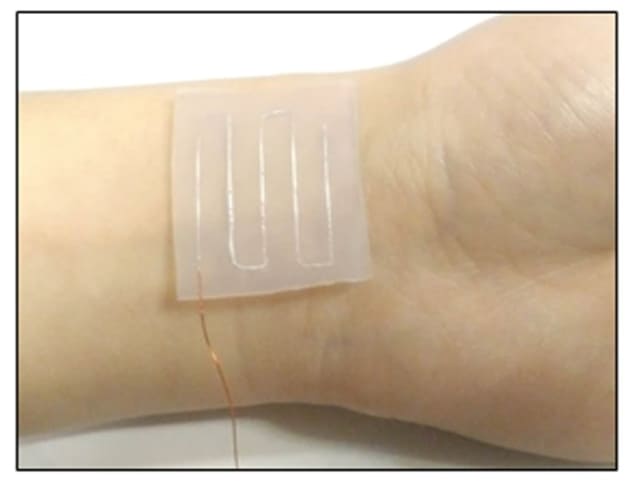

As well as demonstrating the ability to monitor biaxial strain in the nanowires with the inflation of a balloon catheter, the researchers incorporated the nanowire films into a wearable cardiovascular monitor. They were able to detect not just the main pulse but could also distinguish its three components: the main wave as the heart ventricle ejects blood; the “inflection point” of the tidal wave generated by the decreased ventricle pressure; and the reflection of the blood as the aortic valve closes and the ventricle becomes diastolic.

“I was a bit surprised by the good sensing performance of our devices as we did not put too much effort in device structural engineering and optimization,” Wu tells Physics World. “We think such superior sensing performance is primarily due to the strong piezoelectricity and good mechanical deformability of Te nanowires.”

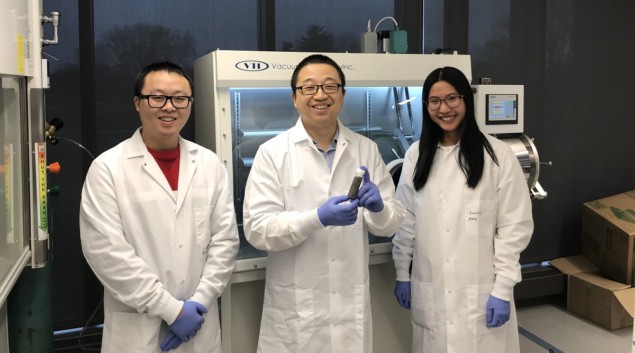

Professor Wu and e-skin

Next steps

Most piezoelectric materials are compounds, which makes these tellurium nanowire devices unique and Wu is keen to better understand their fundamental piezoelectricity. Further investigations will also explore how to improve the devices and the possibility of other applications of tellurium nanowire piezoelectric devices in wearable devices, human-machine interfaces, biomedical treatment, and human-status monitoring. In addition Wu suggests another material that may share tellurium’s promise.

“There is another chiral chain material with the same structure to tellurium. It is selenium! Selenium has a larger bandgap and is expected to exhibit a stronger piezoelectricity than tellurium.” Hot on the trail Wu and his colleagues have already reported on the synthesis, integration, and application of Se nanowires for similar self-powered human-integrated monitoring.

Full details of the tellurium nanowire piezoelectric devices are reported in Nano Futures